Line Balancing (Production and Operations Management)

In production, line balancing is useful tool. Line-balancing strategy is to make production lines stretchy enough to absorb external and internal indiscretion. This strategy involves setting a planned rate of production for necessary materials to be fabricated within a particular time frame. Additionally, successful line balancing requires assuring that every line segment's production quota can be met within the time frame using the available production capacity. This is an efficient device to develop the throughput of assembly lines and work cells while decreasing manpower requirements and expenses. Line-balancing is slightly different from assembly line balancing. Assembly line balancing involved the action of assemble different parts together. It involves many production lines while normal Line-balancing may only involve one production line. Assembly Line Balancing is the problem of assigning operations to workstations along an assembly line, in such a way that the assignment be best in some sense. Since introduction of assembly lines by Henry Ford, Line-balancing has been an optimisation problem of important industrial importance. The efficiency difference between an optimal and a sub-optimal assignment can yield economies reaching huge amount per year. Line balancing technique was used normally in assembly line of the automotive industry which is called ALB. Most of the Small and Medium Industries do not use line balancing method in the production line.

There are two types of line balancing that include Static Balance and Dynamic Balance. Static Balance denotes long-term differences in capacity over a period of several hours or longer. Static imbalance results in underutilization of workstations, machines and people. Dynamic Balance refers to short-term differences in capacity such as over a period of minutes, hours at most. Dynamic imbalance occurs from product mix changes and difference in work time dissimilar to product mix.

The intent of Line balancing is to match the output rate to the production plan. This will help organization to make sure on-time delivery and avoids build-up of surplus inventory. Johnson articulates the problem of line balancing as “a set of non-divisible tasks to be performed, each task has a known deterministic performance time. A partial ordering of tasks by precedence constraints is specified. The problem is to assign these tasks to assembly stations, so that the necessary number of station is minimized.” Line balancing is usual practice to resolve problems occurred in assembly line. It is a technique to reduce imbalance between workers and workloads in order to accomplish required run rate (H.Jay and R.Barry, 2006). This can be performed by equalizing the amount of work in each station and assign the smallest number of workers in the particular workstation. Here the job is divided into small portion called “job element”. The objective is to uphold production at an equal rate (G. Andrew, 2006).

Line balancing operates under two circumstances:

- Precedence Constraint: Products cannot progress to other station if it doesn’t complete necessary task at that station. It should not across other station because certain part needs to be performed before other activities.

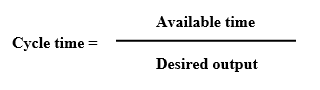

- Cycle time Restriction: Cycle time is maximum time for products spend in every workstation. Different workstation has different cycle time.

Objective of Line Balancing: Following are major objectives of Line balancing procedure. It is used to:

- Manage the workloads among assemblers.

- Recognize the location of bottleneck.

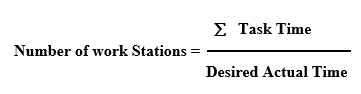

- Decide number of workstation.

- Decrease production cost.

- Assigning task to each work station in such a way that there is little idle time.

Terms in Line Balancing Technique

There is range of terms used in assembly line balancing system. Each of them has their meaning and purposes.

- Cycle Time: Maximum amount of time allowed at each station. This can be found by dividing required units to production time available per day. This is the time expressed in minutes between two simultaneous products coming of the end of production line. Gaither and Fraizer (2001) described that cycle time demonstrates how often the production line can generate the product with current resources and staffing. It is a precise indicator to signify how the line is currently set up to run. The calculation of cycle time takes into consideration of the entire production quantities. If multiple lines are producing the same product, then the composite cycle time is less than the actual lapse time of any individual line.

- Lead Time: Summation of production times along the assembly line.

- Bottleneck: Delay in transmission that slow down the production rate. This can be overcome by balancing the line.

- Task Precedence: It is the sequence by which tasks are carried out. It can be represented by nodes or graph. In assembly line the products have to obey this rule. The product cannot be moved to the next station if it doesn’t complete at the previous station.

- Idle time: A period when system is not in used but is available.

- Productivity: Defined as ratio of output over input. Productivity depends on several factors such as workers skills, jobs method and machine used.

- Takt times: The time needed by competent worker or unattended machine to perform a task. This is usually expressed in minutes. Heizer and Render (2010) stated that takt time is pre-requisite procedure in doing line balancing task. Takt time is the swiftness of production that aligns production with client demand. It shows how fast the need to manufacture product in order to fill the customer orders (Vome lean Briefs, 2006). Producing faster than takt time results in overproduction which is a type of waste whereas producing slower than takt time results in bottlenecks where the customer orders may not be fulfilled in time. There are numerous benefits of using takt time (Heizer and Render, 2010). These include,

- Achieve a steady and continuous flow of production.

- Eliminate the waste of overproduction by producing actual customer demand.

- Improves accuracy of planning.

- Encourage the development of standardize work instructions, promoting quality and efficiency.

- Set real time targets for production that shows operators exactly where their work output should be at any given point of time.

- Establish what-if scenario for customer demand based on flexible manning.

- Work station: A physical area where a worker with tools / one or more machines or unattended machines such as robot perform specific task in a production line (Gaither and Fraizer, 2001).

- Downtime: Downtime explained as the time that is non value added (Chase, et al. 2000). It is often associated with the seven wastes as under:

- Defects: Defect is direct costs of a company.

- Overproduction: One of the severe wastes discourages a smooth flow of goods and services, which may lead to unnecessary lead and storage time. It will lead to the defects which cannot be detected earlier and then the products may deteriorate. It will also lead to excess work-in-progress stocks.

- Waiting: It occur when the goods are not moving or being worked on. It affects both goods and workforce where the waiting time should be used for some value added activities such as training and maintenance.

- Transportation: Any movement in factory can be considered as waste. Double handling and excessive movements are likely to cause damage and deterioration with the distance of communication between processes proportional to time taken. It takes to feedback reports of poor quality and needs corrective action.

- Unnecessary inventory: There is a problem with extra inventory. Inventory will increase the lead time, preventing quick identification of problems and increasing space. Significant storage costs are wasted which absolutely lower the competitiveness of the organization of value stream.

- Unnecessary motion: Involve the ergonomics of production where operation might have to stretch, bend and pick up when these actions actually could be avoided. It not only tires the workers but also leads to poor productivity.

- Inappropriate processing: Over-complexity of a process discourages ownership and encourages the employees to over produce to recover the large investment in the complex machines. It encourages poor quality and takes corrective action.

Steps in Solving Line Balancing

There are four steps in solving line balancing described by G. Andrew (2006).

- Drawing Precedence Diagram: Precedence diagram needs to be drawn to demonstrate a relationship between workstations. Certain process begins when previous process was done.

Determining Cycle Time: Cycle time is longest time allowed at each station. This can be expressed by this formula:

This means the products needs to leave the workstations before it reaches its cycle time.

-

Assigning tasks to workstation: The tasks distributions should be taken after completing a time cycle. It’s good to allocate tasks to workstation in the order of longest task times.

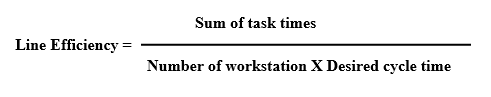

Calculating an Efficiency Line: This is done to find effectiveness of the line. The formula is given by:

Computerized line balancing: Line balancing manually becomes unwieldy as the problem grows in size. There are software packages that will balance large line rapidly. They use various heuristic to balance the line at an acceptable level of efficiency. There are two types of line balancing heuristics which include incremental utilization heuristic and longest task time heuristic. In incremental utilization heuristic, tasks are added to each work station in order of task precedence one at a time until utilization is hundred percent. Longest task time heuristic adds tasks to work station one at a time in the order of task precedence. If there is choice of multiple tasks, longest task is added. It can only be used when each and every task time is less than or equal to the cycle time. There can be no duplicate work stations.

To summarize, a line balance is the modification of the capacity of a line ladder to a particular model mix. The capacity of the line hierarchy is established by the number of tasks and the number of individual capacities in the line segments. The model mix is determined by a number of materials, the rate of the materials and the rate routings, according to which the materials are produced. It is described by experts that line balancing is levelling of the workload across all operations in a line to eliminate blockage and surplus capacity.